Case Study 3 –

Tribotech Composite Housings

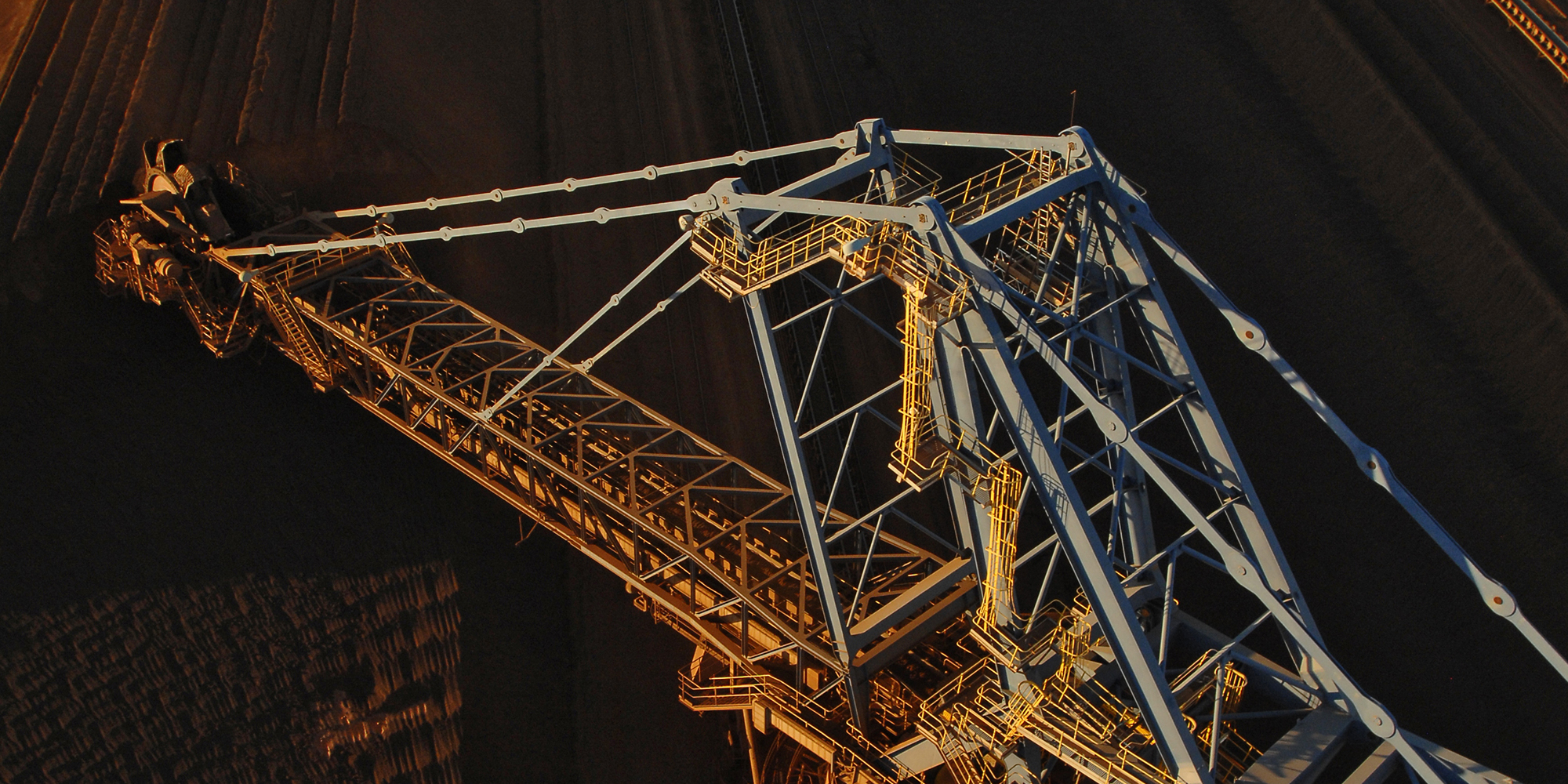

Location of Trial

Perth Metropolitan Area

Client's Problem

Rollers installed in Inverted V-Return Idlers fail within 3 weeks

Roller Size

114Ø x 840mm face installed in Inverted V-Return Idlers

Achieved Roller Life Previous to Trial

3 weeks

Trialled rollers

Tribotech Steel Rollers equipped with HD Composite housing technology

Trial duration

18 months

< Industry steel roller failed due to excessive loading on the housings.

Due to the excessive belt mistracking on one of their belts, the client chose to install a number of Inverted V-Return Idlers on the conveyor. The rollers installed had to sustain a large amount of load and failed within 3 weeks of installation due to the weak steel-pressed housings which produced an uneven load on the bearings.

Tribotech’s client trialled the Tribotech standard steel rollers, equipped with our Composite Housing Technology. The housings allowed a greater load to be carried by the rollers while allowing for an evenly distributed load on the bearings.

Tribotech Steel Roller

Industry Steel Roller

Wear after 12 months

N/A

N/A

Estimated Roller Life

8.5 years

3 weeks – Caused by underdesign of the roller housings.

Weight

11 kg

11 kg

Roller replacement after 3 years

0

52