Case Study 1 –

Location of Trial

Pilbara Iron Ore Minesite

Client's Problem

Quick shell wear failures due to build-up in a high-wear area

Roller Size

152Ø x 945mm face width V-Return

Achieved Roller Life Previous to Trial

PVC Rollers 6 - 8 weeks, Steel Rollers 11 Months

Trialled rollers

Weartech Composite Rollers

Trial duration

12 Months

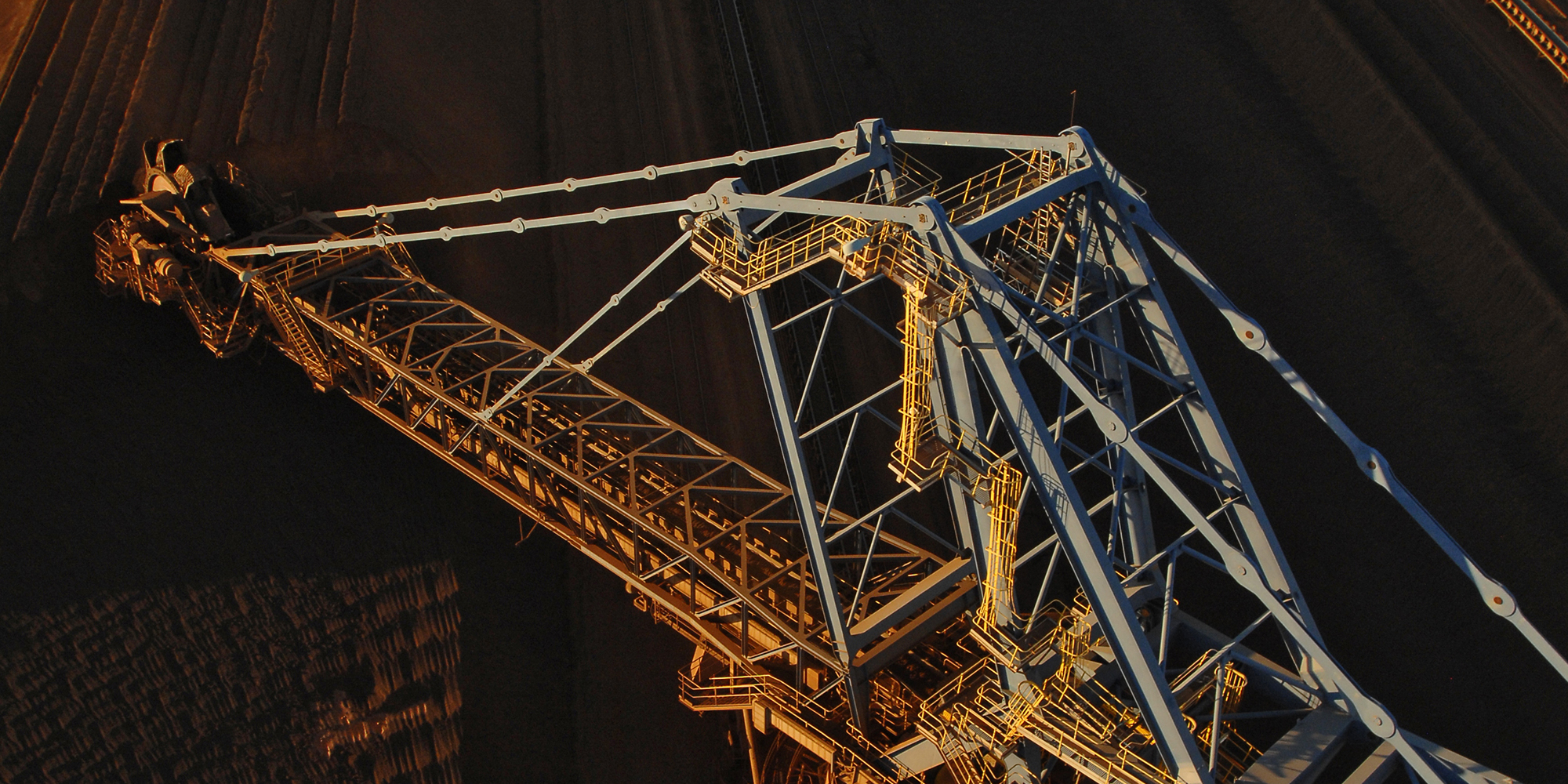

< Weartech Rollers after 12 months of operation.

Due to the high failure rate caused by extremely high-wear and high-tension in the areas of the conveyor belt, the client chose to replace the steel rollers with PVC rollers in order to reduce the risk of damage to the belt. The decision to do so however, came at the cost – a lower roller life of 6 to 8 weeks, due to the poor wear properties of PVC.

Tribotech proposed that the client trial Weartech, which offers the weight and belt-friendly properties of plastic rollers while significantly outlasting the life of steel rollers.

It is projected the Weartech rollers will outlast conventional steel rollers by a factor of 7.

Steel Rollers

PVC Rollers

Wear after 12 months

2mm out of 17mm

(13% of useful life)

Rollers failed within

11 months

Rollers failed within

8 weeks

Estimated Roller Life

7 years

11 months

8 weeks

Weight

14 kg

25 kg

14 kg

Roller replacement after 3 years

0

3

20