Case Study 2 –

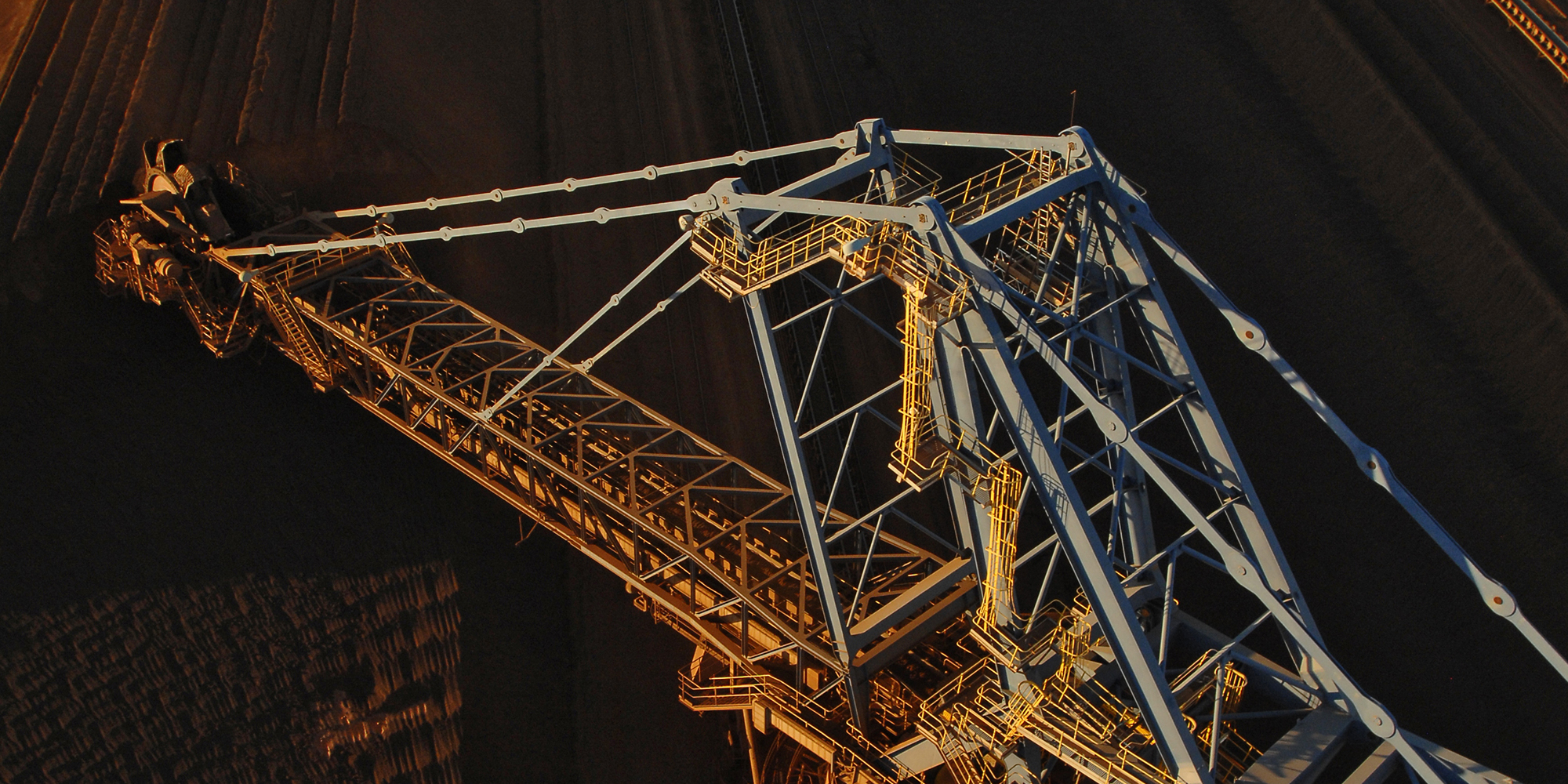

Location of Trial

Port Hedland

Client's Problem

Quick shell wear failures due to build-up in a high-wear area.

Roller Size

152Ø x 538mm face width V-Return

Achieved Roller Life Previous to Trial

Steel rollers with a 40mm thick rubber lagging were used with an average roller life of 6 weeks

Trialled rollers

Weartech and Weartech+ Composite Rollers

Trial duration

4 months

<

Weartech Rollers

after 4 months

of operation.

<

Weartech+ Rollers

after 4 months

of operation.

Due to the large amount of build-up and wear in areas of the conveyor belt, the client chose to use 40mm thick rubber lagged rollers. However, the 40mm thick rubber lagged rollers were extremely heavy and needed to be replaced every 6 weeks due to excessive wear on the shell.

The client trialled both Weartech and Weartech+. Both Weartech products are 45% lighter and resulted in a significant increase in roller life as summarised below.

Industry 40mm thick Rubber-Lagged Roller

Wear after 4 months

2.5mm out of 17mm

(17% of useful life)

1.5mm out of 17mm

(10% of useful life)

>40mm, Rollers

replaced twice

Estimated Roller Life

2 years

3 years

6 weeks

Weight

10 kg

10 kg

19 kg

Roller replacement after 3 years

1.5

1

26